Reshoring: Providing a Safe Harbor for Your Medical Device

Engineers, commodity managers, and operations executives have experienced significant challenges and supply chain upheavals, causing an accelerated evaluation of reshoring and ways to better assure continuity of supply. With the rising costs of freight and port delays, as well as the re-establishment of 25% tariffs on off-shore tooling, a U.S. based supplier development and expanding the domestic supply chain for plastic components and medical devices has become a priority to many organizations.

In August 2020, the U.S. administration took measures to promote the development and manufacturing of critical pharmaceuticals and medical devices to incentivize domestic sourcing. Having the ability to shorten the supply chain and both visit and physically inspect a medical device contract manufacturer as well as improve lead times, compress the development cycle, and avoid tariff and freight costs makes it the perfect time to consider domestic partners.

Key Reasons to Reshore

1. Automation Advancements Lower Labor Costs

One of the key reasons that medical device companies initiated a transition to off-shore sources was the labor cost savings that could be realized. As a result of this and other tangential factors, U.S. manufacturers focused on labor shortages and means by which to increase throughput, improve efficiencies, and enhance quality resulted in many US manufacturing organizations choosing to invest in automation. Through a combination of secondary process and work cell automation, less direct material handling due to end-of-arm-tooling (EOAT), and automating post process part packaging, domestic partners such as Forum Plastics have found significant ways to improve processes, quality, and production.

2. Proximity to Primary Sources of Engineered Resins

North America accounts for roughly 20% of the global plastics industry materials production. With many of the world’s largest producers based in the U.S., this trend continues to rise. Additionally, many manufacturers and distributors are growing their network of warehouses and hubs that will carry inventory of medical-grade materials to support domestic manufacturing. Medical grade materials like Ultem, PSU, Olefin based PP/PE for disposables, and PEEK for implants are all primarily manufactured in the U.S.

3. Easier Engineering & DFM Collaboration

While part cost savings and competitiveness are important, speed to market and meeting critical project timelines is critical to revenue and market share generation. Working with a technical team that is easily accessible can bring significant benefit in helping to achieve program and project related goals and successes. A domestic partner who can support prototyping services, quickly incorporate design changes to parts and/or tooling, and actively participate in early-stage design considerations makes reshoring or engaging with a domestic partner a key value add.

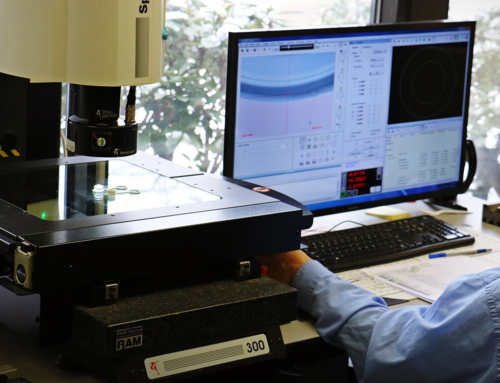

4. Protection of IP and Ability to Know Necessary Processes Practiced

U.S. based manufacturers are typically well versed in the regulatory and quality requirements and certifications critical in medical device manufacturing and contract manufacturing services. Compliance with FDA regulations, ISO 13485 requirements, and employee safety protocols required by OSHA or other state and local agencies are easily verified and monitored. Having the ability to inspect validation documentation and participate in on-site quality audits, T1 trials, or root cause analysis activities is more easily accessible with a domestic versus an off-shore supplier. Beyond this, intellectual property and other trade secrets may be regulated and protected to a higher level in working with a domestic partner such as Forum Plastics.

5. Hidden Cost Impacts

When building tools and products offshore, unexpected delays and hidden costs can become problematic. Following completion of the tool build, the majority of suppliers will need to run tool trials and, in most cases, produce T1 or FAI samples. This requires them to obtain the specified medical grade or engineered resin, as is typically paid for by the OEM and may add additional delays and air freight costs if the material is not available in country. Beyond this, many multi-component devices and assemblies may require additional purchased hardware and components that must be acquired based upon the original BOM and could be burdened by import/export tax/tariff implications on one or more transfers.

As an example, currently tools built in China will have a 20% adder to cover taxes and tariffs to land them in North America. The freight adder fluctuates, but on average it is approximately 25% of the tool cost. If time to market and program costs are critical, port delays, transit time, and transit costs can negatively impact product or device availability, ROI, and market share penetration levels. Partnering with Forum Plastics for both molded components and assembled or finished medical devices can alleviate much of this cost and time impact and help to bring products to market on time and on budget.

Tool Transfer Expertise

Once a medical device manufacturer has determined to reshore and partner with a domestic company, the next step is to learn whether candidate partners have experience and a well-defined process for handling tool transfers.

At a high level, Forum Plastics follows the following process:

STEP 1. Customer provides tooling information to include:

Sample or last run parts, if available

Step 2. Forum conducts a mold and part design review based upon this information and provides a quotation. Following agreement to terms and receipt of the tooling, Forum will:

STEP 3. If the tool requires no maintenance or repairs, the following steps ensue:

In the event tooling requires additional service or repairs in order to address any issues that may arise that could impact the molded part adherence to the specification, Forum works closely with clients to determine the most efficient and effective path forward.

Forum Plastics provides on-site tool maintenance and upkeep at regularly scheduled intervals that are tracked and monitored through ERP systems. This service is provided at no-additional charge. Forum’s in-house tool shop is able to perform all routine maintenance, minimizing any impact to critical part supply chains and provide continuity of supply. If a transfer tool is close to the end of tool life or if repairs cannot remedy the problem, Forum’s tooling finance program can keep the NRE costs down and minimize budget impacts.

Forum Plastics has a legacy of outstanding performance and quality in support of tight tolerance and very precise molded components. With years of support and experience in the medical device and life science contract manufacturing industry, Forum is the ideal partner for reshoring products and supporting tool transfers. Contact us today at sales@forummolding.com or visit us at https://forummolding.com/ to learn more.

Stay Connected

Sign up to get updates from Forum