We welcome the most challenging part decoration projects.

Pad printing is a versatile, proven technology for imprinting the most challenging 3-D surfaces and materials. Laser marking is a general technique in which the laser interacts with the material to create a durable, high-contrast mark on the surface. At Forum, we can precisely print your artwork just about anywhere you can imagine. Compound curves, textures, and recessed areas are ideal for pad print technology, and we have the experience to deliver to your needs. We offer in-house leading pad printing and laser marking services for difficult or irregular surfaces. With our automated and semi-automated print stations and specialty inks and pre- and post-surface conditioning treatments, we welcome the most challenging projects. Learn more about our core services below.

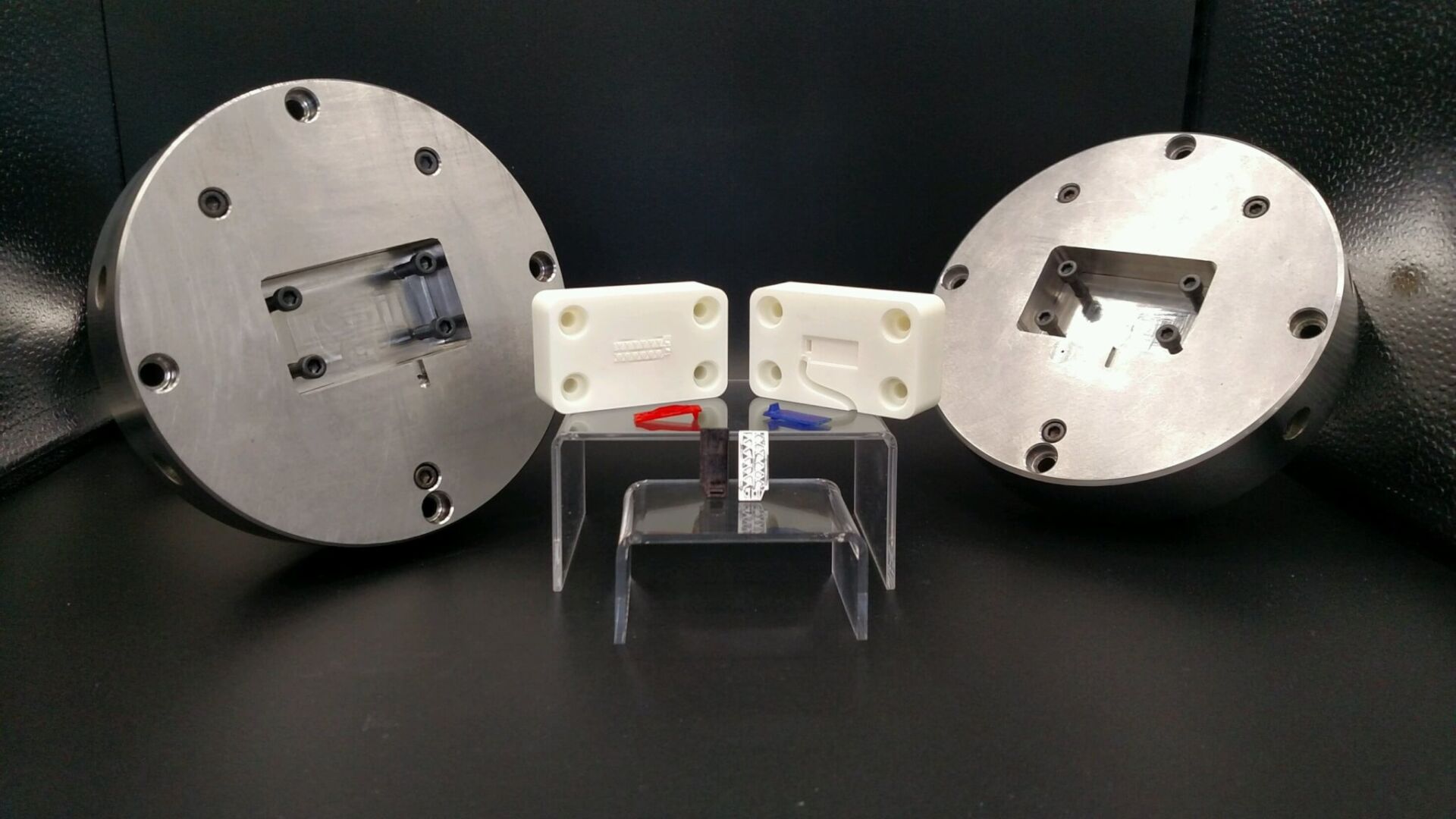

Pad Printing Examples

Complementary Capabilities & Applicable Markets

Forum can manage molding, printing, purchasing, and assembly so you receive one item inspected and certified. Learn more about our contract manufacturing and complementary services below.

Services overview:

Pad printing capabilities

Pad printing on difficult and irregular surfaces is one of Forum’s specialties. With over 25 years of molding experience, Forum can precisely print your artwork on nearly any surface.

Download the pad printing capabilities overview to learn more about our services.