We have years of mold tooling expertise.

As a responsible partner in your product supply chain, our goal is to have you benefit from our years of mold tooling expertise. Whether the mold or tooling is built within our facility, Forum is in control of the design and end quality of the mold. Forum will take your part / component design package and offer you the most competitive options for molding and producing your parts. Our engineering staff has the experience and expertise to design tools that will produce high quality components for years of service. In addition, we can offer the most cost-effective options without sacrificing the quality of the tool.

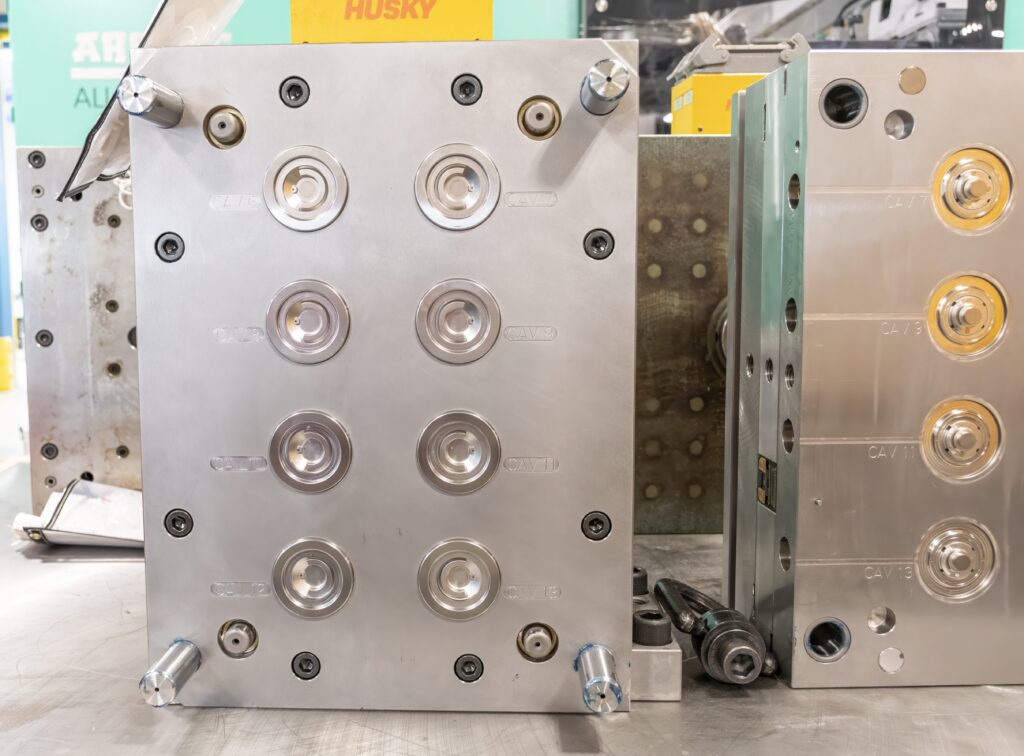

Full Service Tool Room

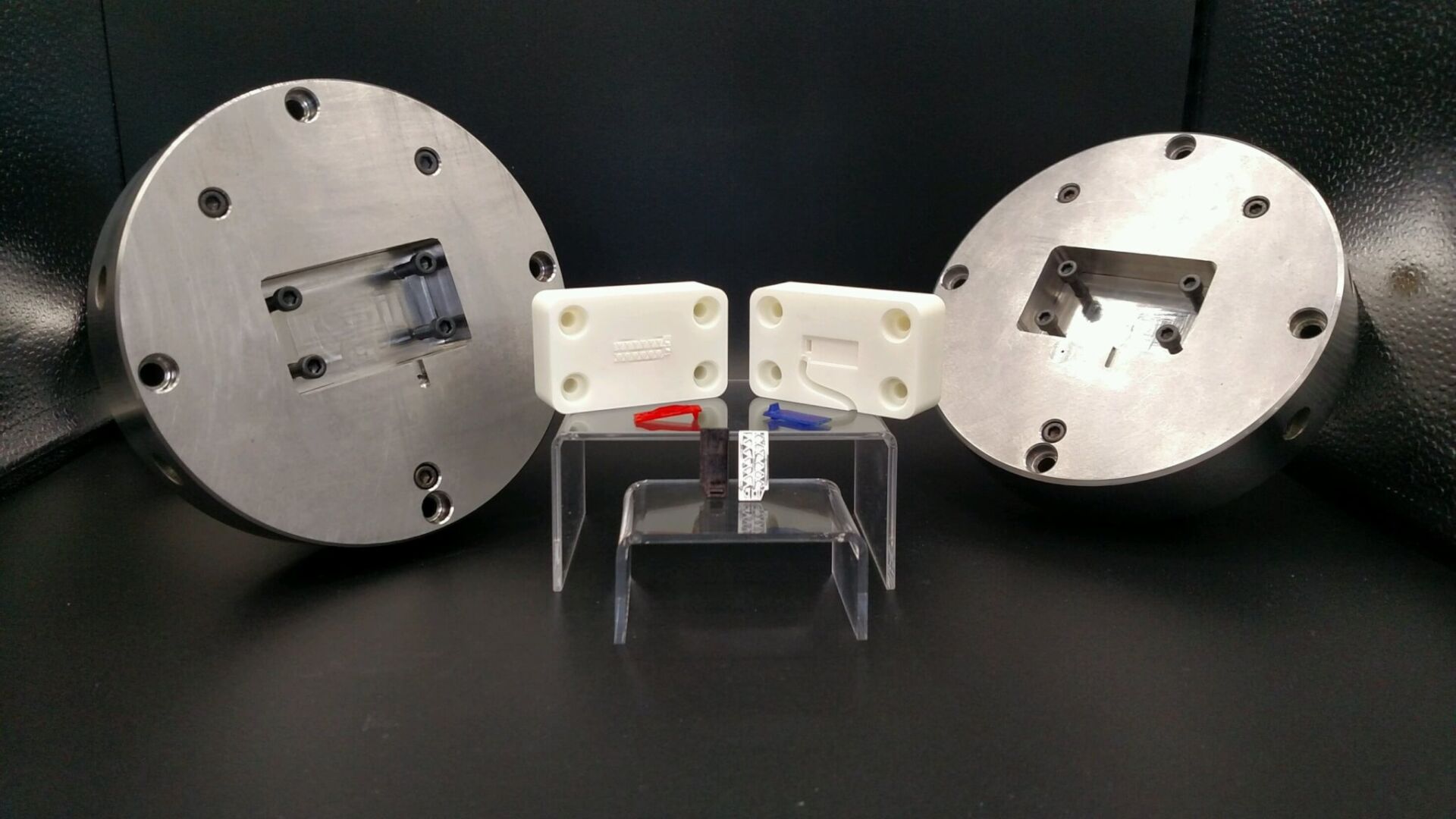

At Forum we are continually investing for the future. Our mold tool room is fitted with the latest equipment from computerized CNC machining centers and EDM machines to our precision grinding and polishing centers. At Forum your tools will receive the highest level of care and service from tool design and manufacturing thru its lifetime of production services.

Forum’s Tool Transfer Program Solves Quality Issues for Surgical Device Company

A surgical device company was experiencing quality issues with a molded part produced by a competitive injection molder. Forum identified areas of improvement and yielded a range of components that met full validation protocol while producing parts with zero defects.