Your medical device partner, from prototype to production.

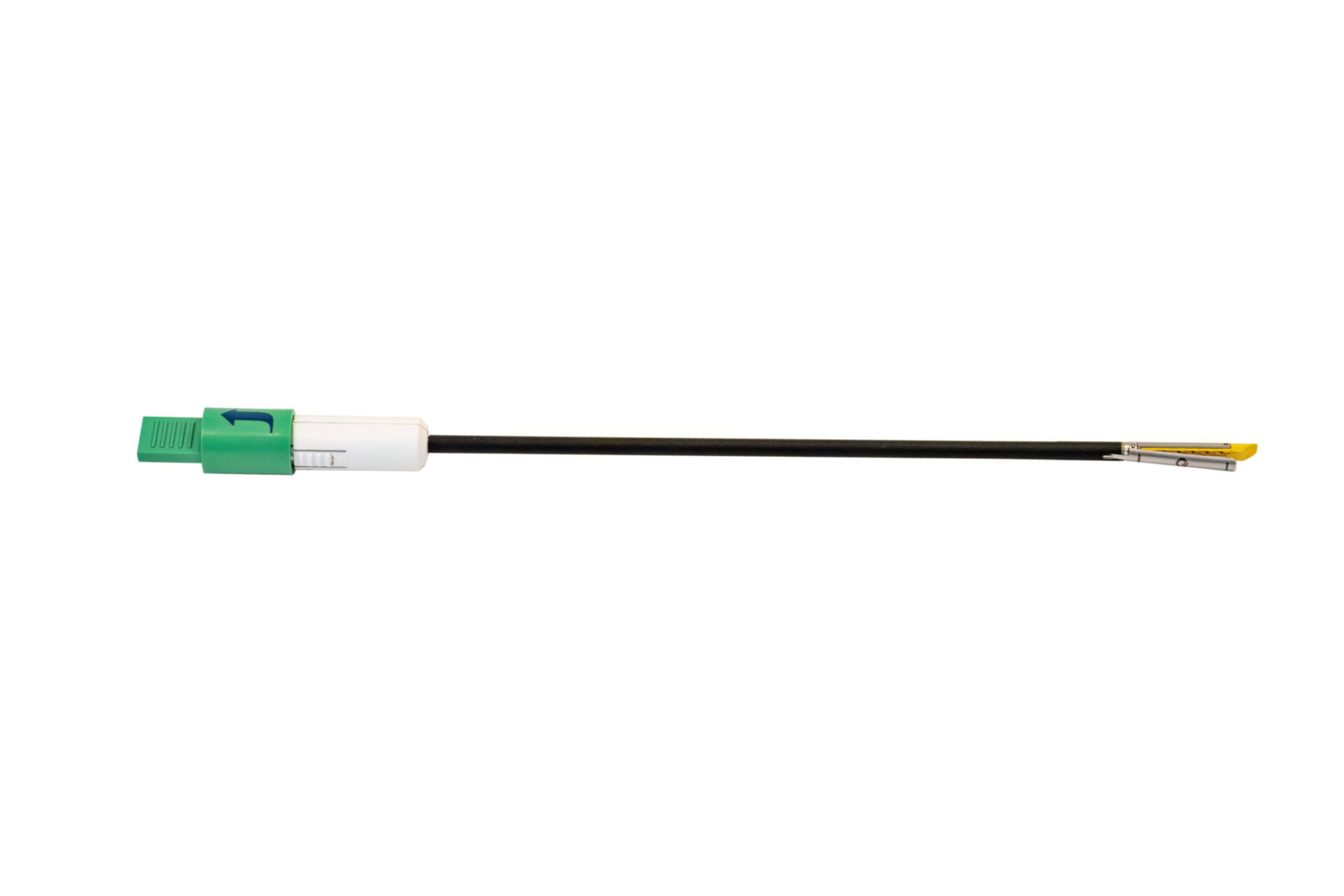

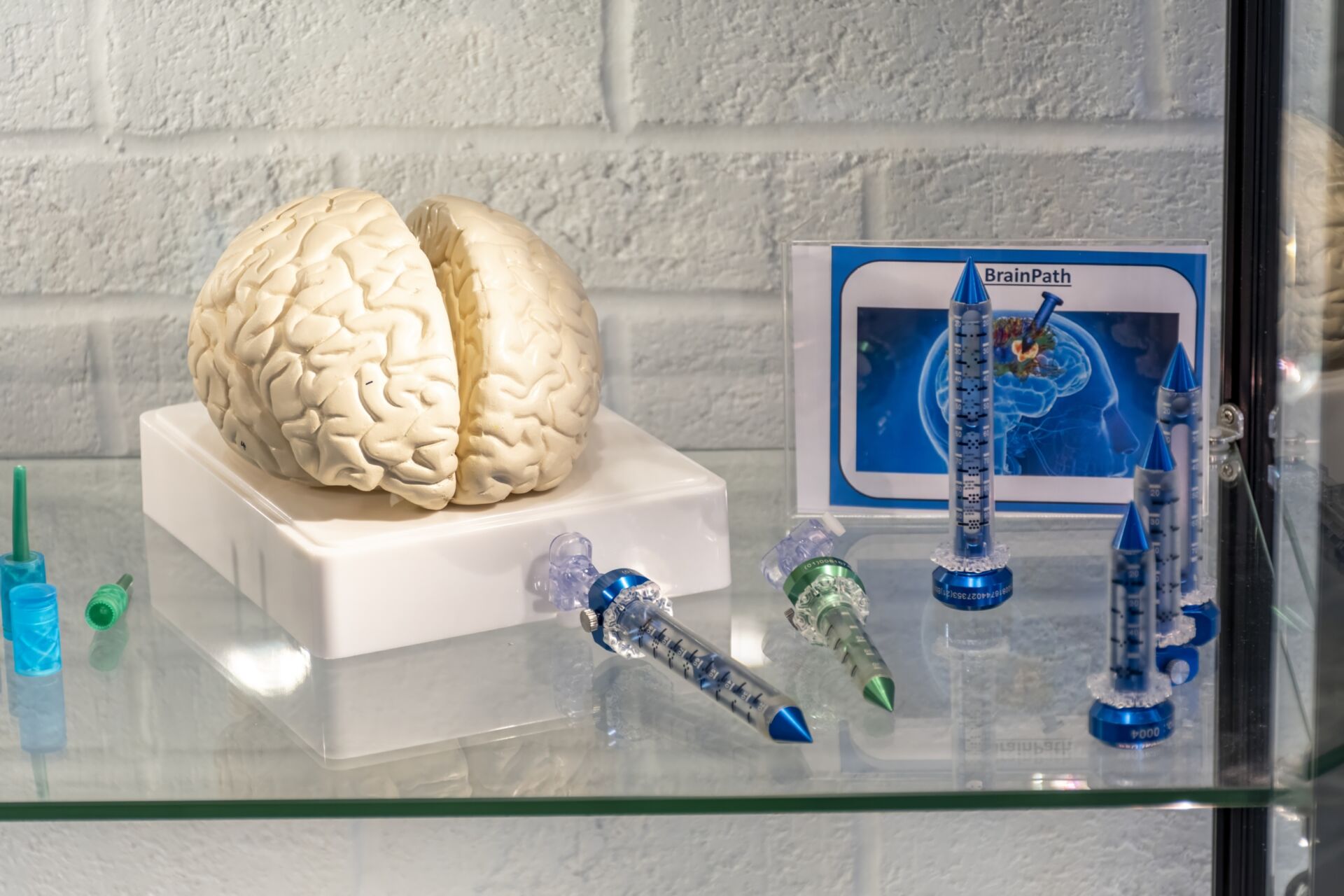

For over 25 years, Forum has consistently produced superior medical injection molding and micro molding solutions for the medical, pharmaceutical, and dental industries. Forum offers expertise in manufacturing Class I, II(b) and III components and devices using a wide range of medical-grade resin materials.

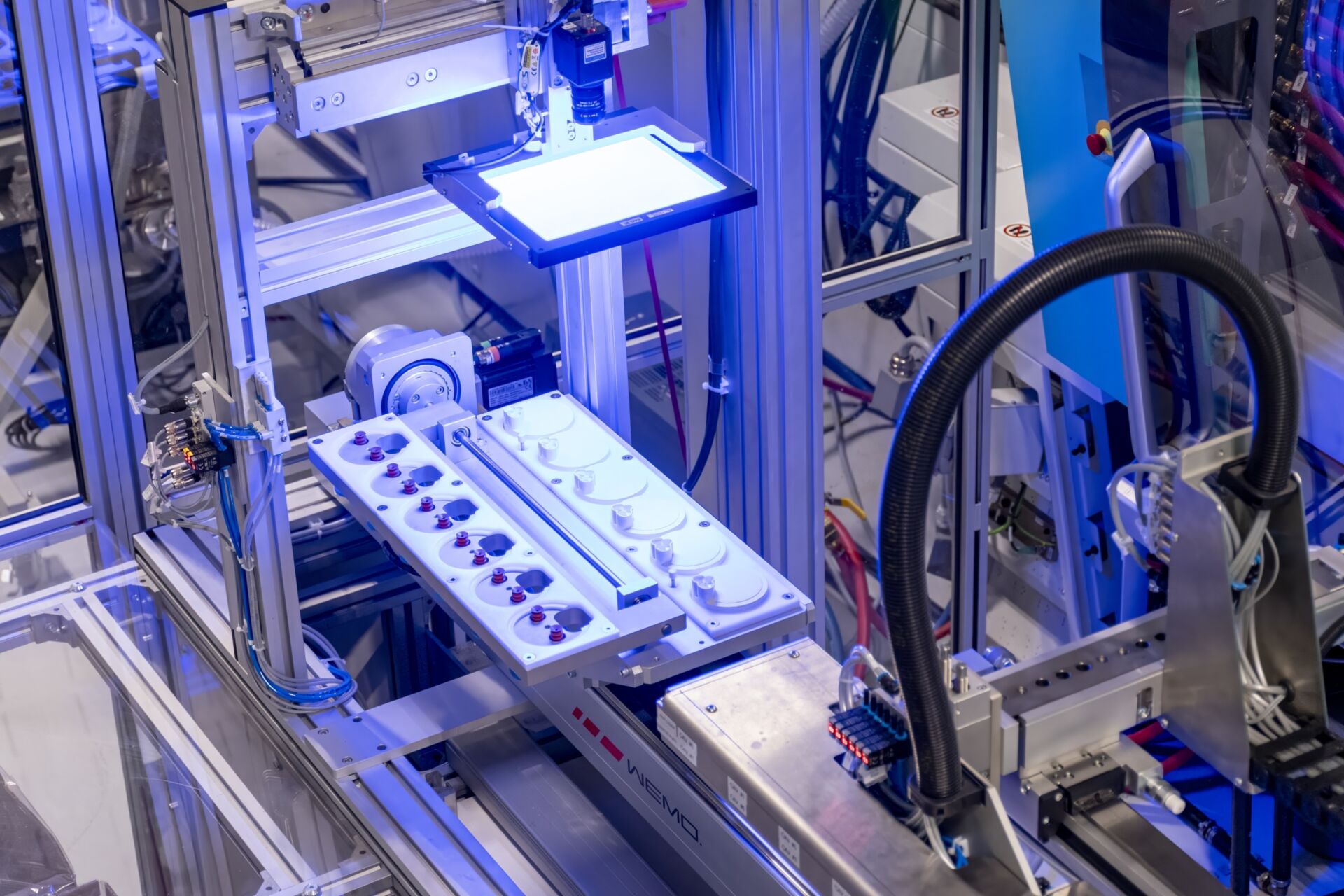

In our Food and Drug Administration registered facility, medical device injection molding operations can be completed in our general molding facility or our certified Class 7 Cleanroom Molding using scientific injection molding principles, state-of-the-art injection molding machines, and automated secondary operation equipment. Our commitment to quality, service, and scientifically backed molding processes means our clients draw upon our medical device injection molding services to achieve results faster.