Going Lean: An Inside Look at Forum’s Commitment to Lean Principles

Does your molding partner embrace a lean philosophy? And if so, do they practice continuous improvement in areas outside of molding? These are important questions that OEMs should be asking their current molding partner and prospective partners.

The idea of being lean means creating more value for the customer while minimizing waste. An injection molder that is looking to reduce waste, improve efficiencies, and increase employee engagement outside of molding and manufacturing is likely to also be looking for new ways to create greater value for their customers. By passing on the lean benefits as a value add to the customer, the customer’s final goods and services are leaner with minimum waste.

The benefits of embracing lean philosophy in an injection molding organization are significant. To demonstrate, let’s spotlight a few recent lean activities in the Forum Plastics organization that fall outside of traditional manufacturing applications.

#1 Spotlight: Metrology Department

Background

One area where we leveraged lean principles to improve processes is in our metrology department, specifically related to validations. Our previous process for parts inspection relied on a spreadsheet. There was little visibility into the status of each part and inspections could be delayed.

Lean Tool: Visual Management

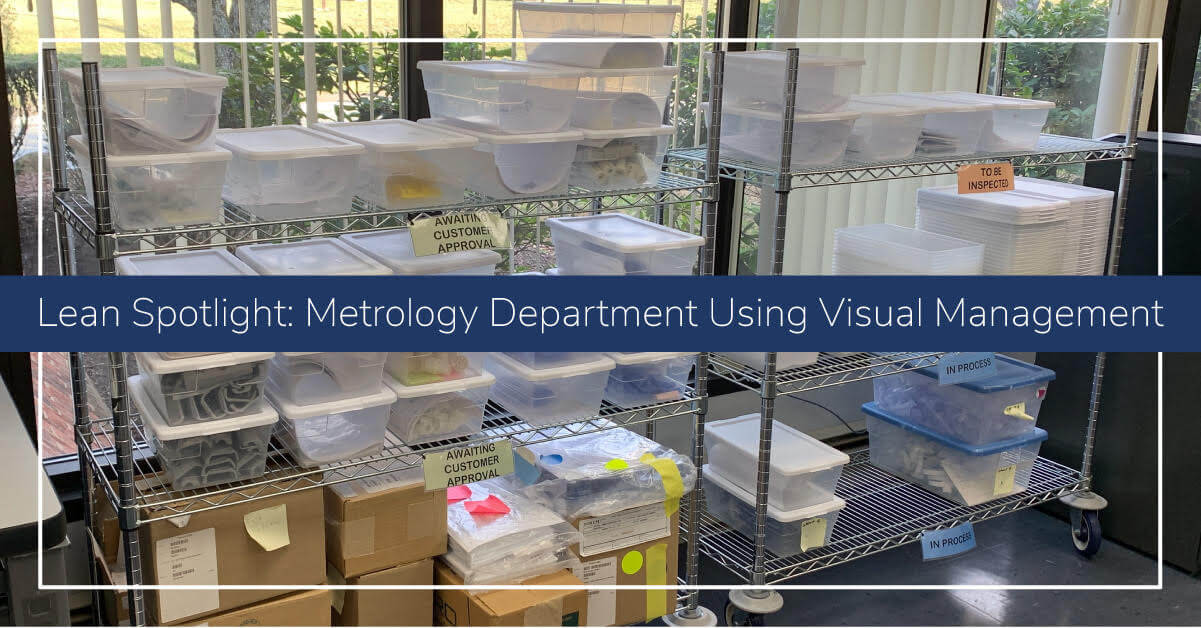

Our updated process uses the lean principle for visual management. A rack-and-bin system is used to track the progress of each inspection. Rack shelves are labeled “to be inspected,” “in process,” and “ready to submit.” This visual inventory improvement helps to identify where each project is in the process and provide greater visibility for all staff.

Customer Benefit

Improved efficiencies in the metrology inspection process have shortened lead times for validating customer product.

#2 Spotlight: Maintenance Department

Background

In our maintenance department, two areas needed to be reorganized. The first was a compressor room hallway which kept file cabinets containing process sheets, and the second area was the main maintenance room. Many items were stored in shelving units and without proper identification, time was wasted when searching for items.

Lean Tool: 5S

With the help of our new maintenance supervisor, the areas were reorganized using the lean principle of 5S: Sort, Set in Order, Shine, Standardize and Sustain. All items were identified, waste was removed, and cabinets were reorganized. Process sheet cabinets were moved onto the molding floor to reduce the distance and time required for a set-up technician to retrieve the process information. Our team found many duplicate machine spare components and identified what items needed to be ordered to have parts in stock for machine repairs. We also identified new improvements to enhance the work environment by adding workbenches which allow for greater workspace.

Customer Benefit

By organizing the maintenance areas, our maintenance team and set-up techs are better equipped to oversee machine repairs in a timely fashion with in-stock parts. The improved efficiencies have led to faster repairs, giving customers predictable delivery of quality products.

#3 Spotlight: Shipping Department

Background

Previously, all customer shipping documents, including packing slips, Certificates of Compliance, BOLs, commercial invoices and inspection data, were sent to customers via email. The process was time-intensive and sometimes required documents to be resent manually.

Lean Tool: Digitization

Our new process involves having all customer documents electronically loaded into a file-sharing portal that is accessible to the customer.

Customer Benefit

By digitizing all documents and creating a secure centralized location, the customer has access to all documents at any point in time. This also reduces the manual task of resending documents via email.

Looking Ahead: Forum’s Plans for Continuous Improvement

Forum is committed to continuous improvement, sustainability, and waste reduction throughout our organization. We believe that passing on these benefits to our customers is what makes us a premier injection molding partner. For example, leveraging lean principles, we increased on-time deliveries from 88% in 2019 to 94% in 2020.

Our entire operations and strategic planning leverage lean principles, and we continue to implement lean management with the direction of our certified Lean Six Sigma Black Belt employees.

As we look ahead to the new year, Forum Plastics is eager to implement lean improvements to our manufacturing processes and areas such as quoting, document control, and in-process inspection. To learn more about Forum’s lean activities, contact Doug Hungerford, Director of Engineering or Andrew Butkus, Engineering Manager.

Stay Connected

Sign up to get updates from Forum