As an engineering-based company with a customer-first approach, Forum supports customers through every step of a project.

Forum Plastic’s engineers and program managers work directly with clients to provide support through all project phases, from concept, planning, and design for manufacturing to mold construction, FAI, and final parts approval to full-scale commercialization.

Each program manager serves as a consistent point of contact committed to providing quick response times, optimization recommendations, and value-added support.

Our customer-focused approach provides:

Engineering Solutions

Quick Response Times from a Dedicated Project Team with Primary Points of Contact:

Project Management Services:

From Concept to Manufacturable Design

Forum’s engineering team can take your concept and turn it into a manufacturable design including complete models and manufacturing drawings. We can perform a wide range of analyses such as tolerance stacks, static and dynamic loading, and other Design for Excellence (DFX) practices.

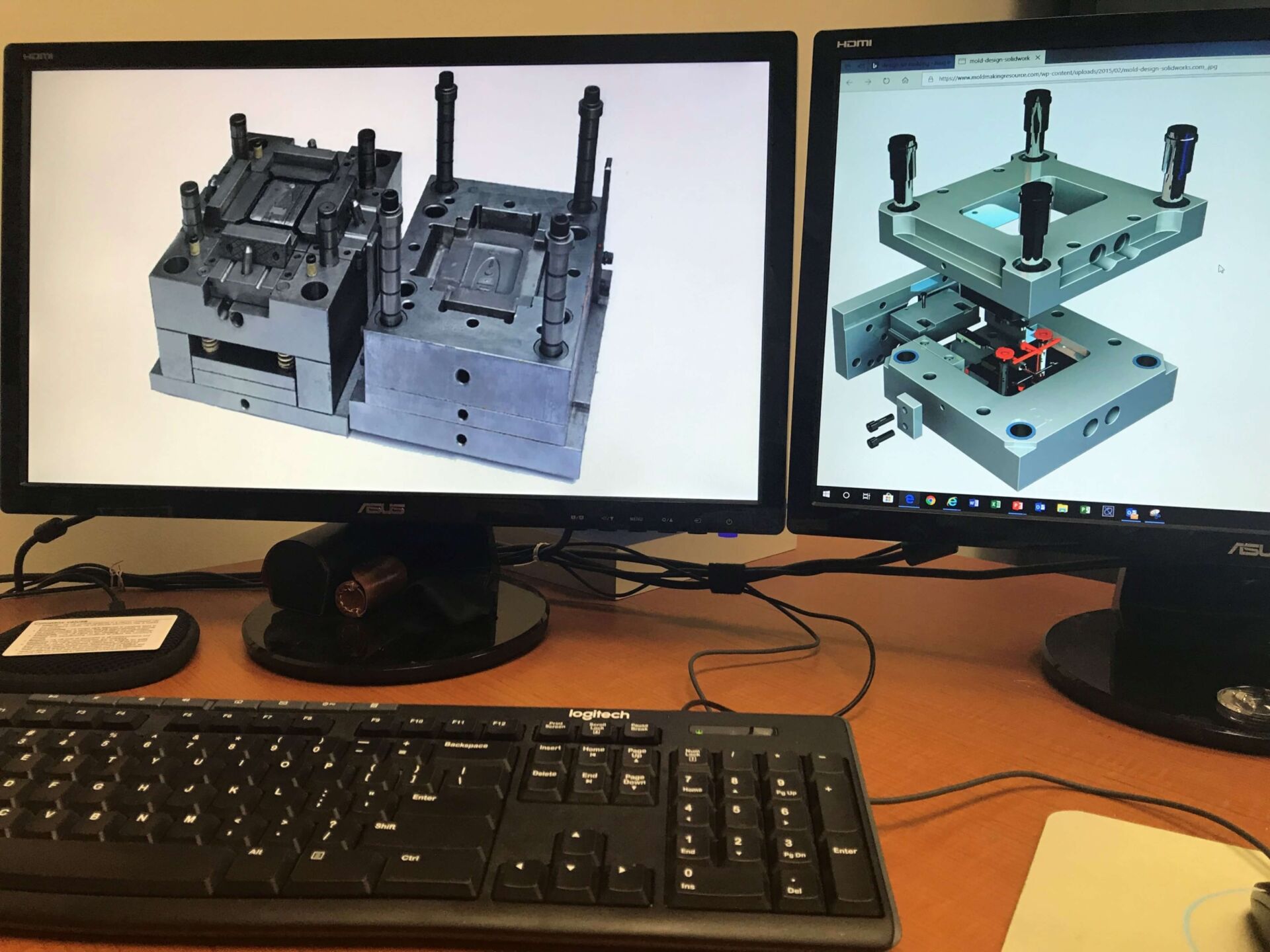

SolidWorks: Our CAD Platform

Our SolidWorks CAD platform enables us to provide the most comprehensive analysis of a product before we begin to fabricate the injection mold. This includes gate location selection, thickness analysis, warpage prediction, and weld line identification among other items of moldability.

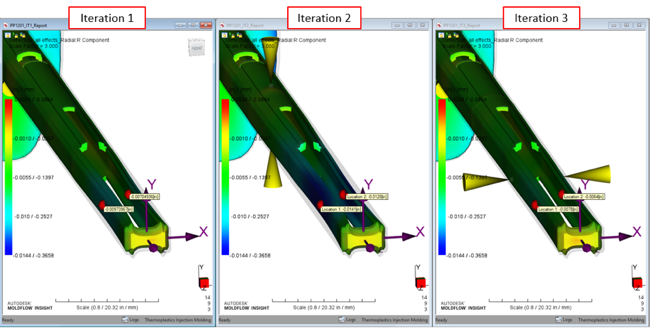

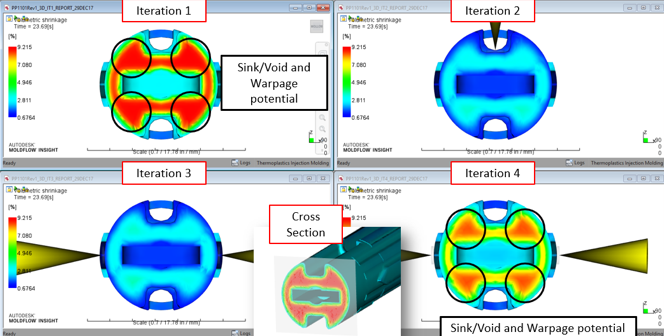

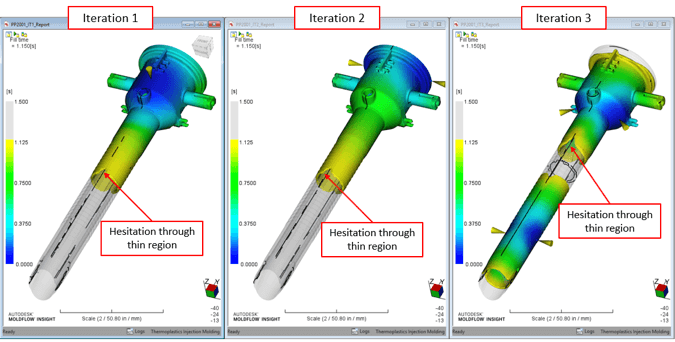

MoldFlow: Improving our Molds

MoldFlow software is used to analyze the molding process and provide recommendations to the design to improve mold simplification and molded product robustness.