9 Benefits of Prototyping With Forum Plastics

Many injection molders will tell OEMs that they are the ideal partner for early supplier involvement (ESI) and that they can help OEMs with product development from concept to completion. But when one pulls back the curtain, they often find that, when it comes to prototyping capabilities, injection molders may outsource this service to a third party.

What if you could work with an injection molder that actually can be your partner from “womb-to-tomb” — a strategic partner that can work with you throughout the lifecycle of your product?

Forum Plastics has made the investment and commitment to be your solution provider from the initial concept and design phase into sustaining production. OEMs have come to understand the benefits of leveraging Forum’s expertise through the entire development process, from start to finish.

Benefits of Partnering With Forum Plastics During the Prototyping Process

- Rapid prototypes help refine the design and allow you to make necessary adjustments before investing in production tooling.

- Prototypes optimize the design and aid with cost avoidance early in the development process.

- Prototypes allow for a better definition of the tooling strategy, including considerations such as gate locations and parting lines.

- Prototypes refine the production manufacturing process or where it can be improved from a quality and repeatability perspective.

- It allows for the testing of different materials to validate the best engineered resin for the application.

- It can provide confirmation of part geometry being manufacturable or if complex geometries can be eliminated to reduce costs.

- It helps determine the best secondary operation or assembly process.

- Manufacturers can bring products to market faster because typically there will be fewer revisions to get to a production tool.

- Prototyping can assist with developing and testing packaging or shipping methodology.

Save Time and Money With Forum’s Prototyping Solutions

Forum offers unique prototyping solutions to fit your product development needs. We have made the investment to support 3D printed parts with our Project 3D system. Our customers leverage this technology for everything from low-volume production to design validation.

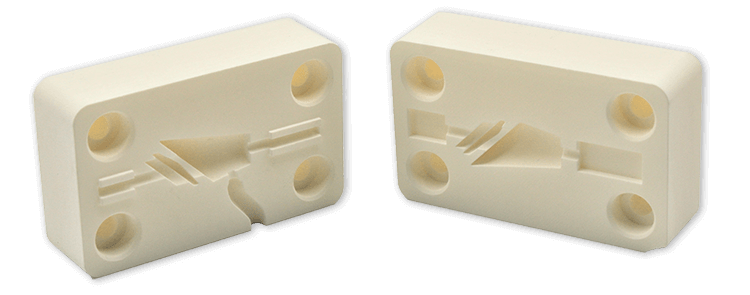

To save time, many customers leverage Forum’s ability to 3D print to create mold inserts that can make fast, functional parts. In some cases, this has allowed Forum to provide functional parts within one week. The key benefit of this capability is that it allows OEMs to quickly run parts with the engineered resin that will be used in production.

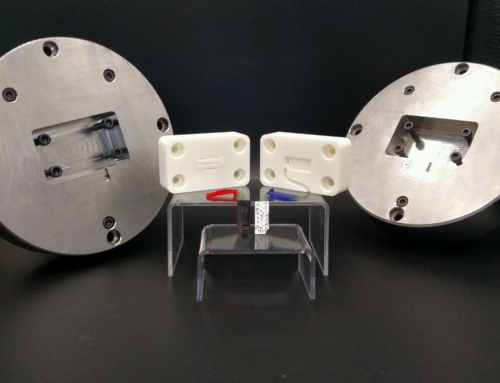

Additionally, when it comes to tooling, Forum has invested in a modular molding system that keeps the upfront tooling investment lower. These cavity block solutions are Class 103 tools that can support low-volume, limited-production runs while meeting production quality standards.

3D Printed Cavity

3D Printed Parts

Modular Mold Frame

Committed to Being Your Co-Development Partner

Some injection molders may talk the talk of being your co-development partner. But Forum has made the commitment and investment to walk the walk as your ESI solution provider. To learn more about any of these prototype solutions, contact Doug Hungerford, Director of Engineering.

Ready to get started? Submit your prototyping quote online.

Stay Connected

Sign up to get updates from Forum