8 Cost Avoidance Factors for Part and Tooling Design

Cost savings and cost reduction will always be focuses for OEMs developing and launching new projects. But focusing on material and labor costs can only take you so far. That’s why it is critical to identify the right custom molder who excels at upfront cost avoidance in the part and tooling design phase. Early Supplier Involvement (ESI) can yield the needed results to provide long-term savings over the life of your program.

Forum has partnered with Tier 1 OEMs for over 25 years, providing design for manufacturing (DFM) support to improve part quality and also collaborating with customer engineering to drive cost out in the initial product design phase.

When Forum engages with an OEM on a new project, there are key design considerations for cost avoidance:

- Undercuts

- Tight tolerances and wall thickness

- Cosmetic finishes, appearances and textures

- Adding draft

- Coring

- Mold/tool optimization

- DFM analysis

- Part complexity

Undercuts

Undercuts can complicate and, in some cases, prevent part ejection, so eliminate them if possible. Undercut features add cost to the tooling but also can have an adverse impact on part quality and yields. The simpler the part, the easier it is to mold. Engineers do face the challenge of designing complex parts, and sometimes undercuts are truly necessary. If, for example, a part requires several undercuts, you may need a side action, sliding shutoff, or lifters. One alternative may be using sliding shutoffs, pass-through cores, or by changing the parting line and draft angles to provide an easier mold build.

These reduce tooling costs as you avoid additional pieces to the mold that add to manufacturing costs. In addition to the rise in manufacturing costs of using hand-loaded inserts, this also may have an impact on your piece part price because of longer cycle times and manual mold operation.

Tolerances and Wall Thickness

Forum has the experience and expertise to design tooling for tight tolerance parts, but there is a direct correlation between tight tolerance and tool costs. Another key factor to consider is nominal wall thickness and choosing the right materials. Forum can aid your product development with both factors in mind and can provide guidance on the appropriate wall thickness. When considering tolerance and part thickness, consider whether the part is structural, will this impact durability, or make the part more fragile.

Cosmetics

When it comes to evaluating cosmetics on your part, there is a delicate balance between want and need. The prettier the part does drive tool cost. If the tool requires bead blasting, texturing, EDM, high polish or an SPI-A2, that fine finish impacts E2E costs. If these finishes can be avoided or a lower cost alternative is an option, that should be up for consideration.

Adding Draft

Draft or tapering of the part can provide several benefits to part design. The main advantage is that it makes it easier to remove the cooled part from the mold. Introducing draft angles can also reduce the odds of part deformation. Forum has experience with recommending the right draft that takes wall thickness, shrink rate, and material into consideration.

Coring

Coring a part, or making the inside hollows, offers many benefits, including reduced part weight, material usage, and a better part by reducing the risk for sink marks, voids or part stress. Coring is key for reducing part mass, but it is necessary to properly design the part wall as well as add ribs to make sure part strength is not compromised.

Mold/Tool Optimization

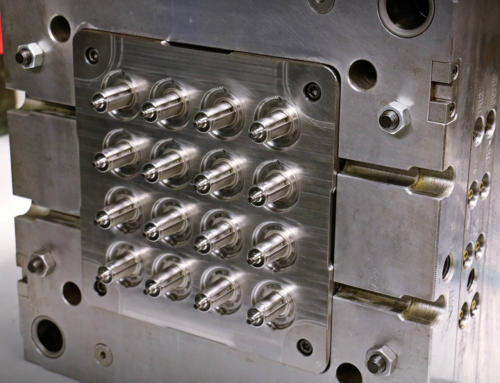

Forum has partnered with many development engineers on the right tooling options that take into consideration not only the piece-part cost objectives, but also program life. Forum offers the best cavitation solution based on volumes, part size, and geometry.

Another factor to take into consideration is family tooling. It isn’t always necessary to build an individual tool for each part, especially if all the components use the same material, they are purchased as a set, or if they can fit into the same cavity. For some applications, Forum also offers Master Die Units (MUD) as an option to keep NRE investments inline with your project budget. Forum is one of the only injection molders to provide tool financing.

DFM Recommendations

Forum has an experienced staff of engineers and mold designers that can provide a detailed Design for Manufacturing (DFM) analysis. This identifies potential problem areas or opportunities for design improvement. Forum provides the DFM report and will review and make suggestions for alternative options.

Part Complexity

A key cost driver of any injection molded part is size and complexity. With complexity comes cost adders for tooling, challenges with proper mold flow, part filling, and increased cycle time. Designers often try to take advantage of improvements in engineered resins and processing technology to make one larger, more complex part as opposed to a less complicated part made up of two or three parts that could be assembled leveraging ultrasonic welding or other part joining techniques. The lesson here is just because a part can be designed in a 3D model doesn’t mean that it can be molded efficiently or cost effectively.

Forum’s Commitment to Cost Avoidance

Our team is committed to working with you and your team on these eight factors to develop a tooling and production part strategy that targets cost avoidance at the concept stage of the project. We take a holistic approach, looking at the entire scope of the project beyond per-unit costs. Part of that process includes evaluating the materials to make sure that all facets are considered, including application and industry requirements, strength, durability and functionality. Beyond that, Forum considers material availability, ease of processing, and total E2E costs.

Forum has also developed strong partnerships with the leading suppliers of engineering-grade resins and collaborates with our customers to determine the optimum materials for the application and the product. When Forum is part of your ESI strategy, we take all of these factors into consideration to aid you with your product design and development.

Stay Connected

Sign up to get updates from Forum